|

ure scrap refers to ordinary scrap mixed debris (including slag, clay, rubber and other non-metallic debris and non-ferrous metals) will be separated and attached to the surface of the oil clean scrap a raw material. Iron and steel enterprises have been widely used in foreign countries, in China is still in its infancy.

At present, China scrap consumption at a low level (178Kg / ton of steel or so), as China's rapid economic development, structural parts, automobiles and household appliances will increase the amount of scrap steel to produce a lot of waste, it will become the main raw material, if tons of steel scrap reach the world average consumption (400kg / ton of steel above), the quality of scrap iron and steel production process and quality levels of steel products will play an important role. Scrap finishing to improve efficiency and reduce harmful impurities into the furnace is very useful. Today most companies use scrap steel finishing method simply grading and finishing dimensions, attached to the surface paint on the scrap steel, oil and debris removal lack of means. Jinan Iron and Steel as a circular economy pilot units, using pure scrap already started.邹平玉 Yuxi charge Ltd., Jinan Yongtai Trade Center two units each built a 200,000 tons of pure scrap production line, using pure scrap steel to provide a strong economic conditions.

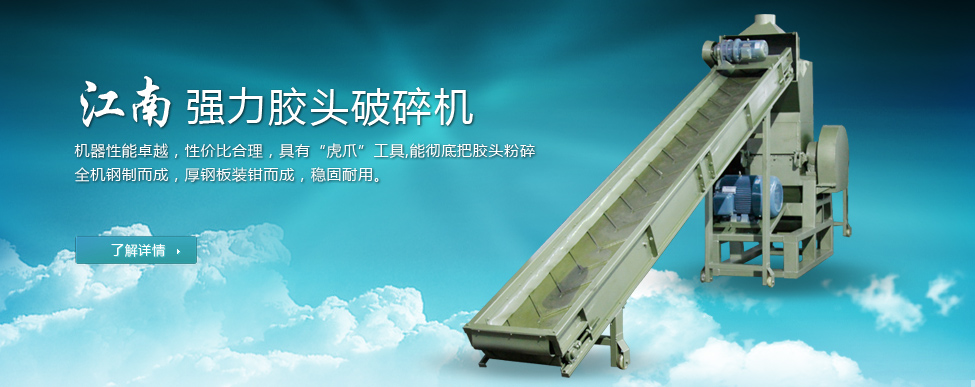

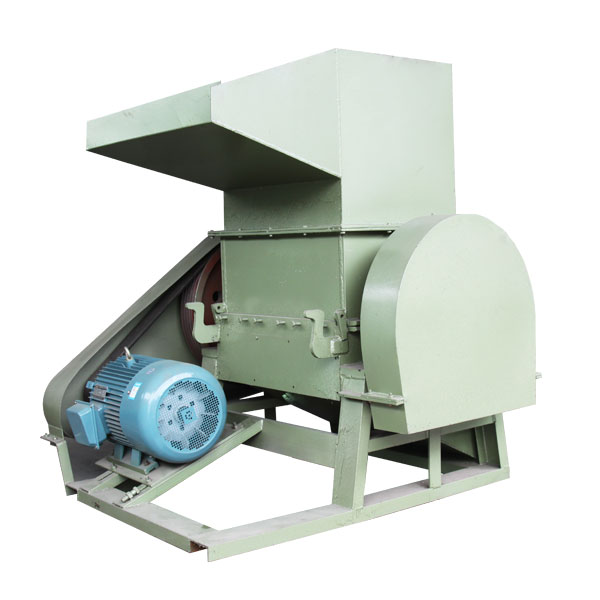

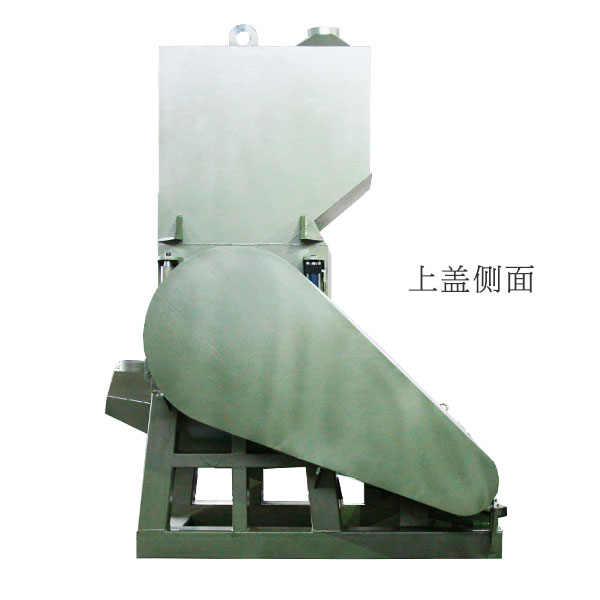

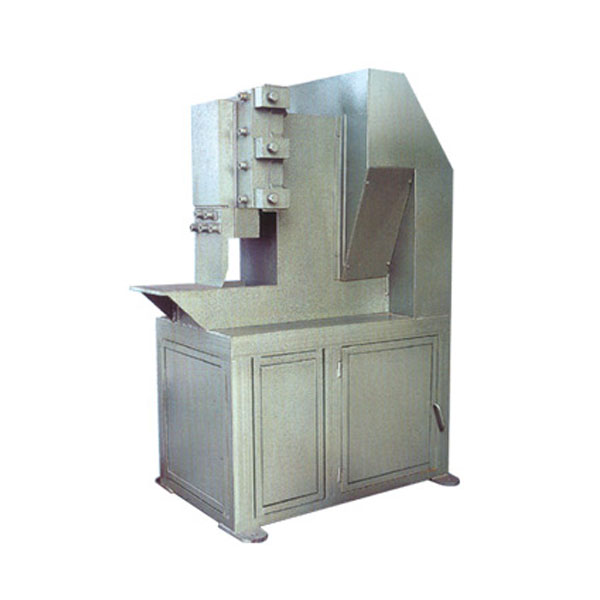

Pure scrap production process: the social scrap recycling ordinary into roller compacted by feeding conveyor device, and then crushed into irregular shape after scrap crusher, crusher is in the hammer to drop, squeezed, torn or lump Slug, the crusher conveyor belt into the grid and detritus magnetic sorting system, the ferrous metals, non-ferrous metals and non-metallic separated, and ultimately achieve the purpose of classification stacked.

Use pure scrap advantages:

1. Scrap inspection solve difficult problems. Current scrap iron and steel enterprises are the thickness of a standard classification, are: heavy, medium, small, lightweight materials, machines and iron, according to various enterprises in the region, the actual situation of the unit established scrap acceptance criteria vary. But there are common problems, relies entirely on artificial visual inspection means, due to the different various types of scrap prices, to examine a great deal of difficulty, type of scrap steel scrap operators determine the impact on the effectiveness of large, often prone to both supply and demand differences. After scrap crushing production line treatment, do not categorical, testing becomes very easy.

2. metal recovery and stability. Social scrap metal recovery common feature is unstable, low metal recovery less than 80% (especially small and light scrap materials), high metal recovery is greater than 90% (e.g., heavy scrap). Metal recovery instability is not conducive to fine production, especially great impact on the smelting rhythm. Scrap metal recovery process through pure crushed at around 98%, due to differences in material type, the error is within 2%. Jigang measurement results for pure scrap metal recovery, basically stable at between 97-99%.

3. Avoid debris into scrap, reduce slagging difficult. Due to the non-metallic inclusions in steel scrap composition is very complex and difficult to test, increasing the converter slag process. After processing the scene of the observation and analysis of pure scrap garbage, debris are: rubber, attached to the metal surface of the paint, soil, slag, copper, aluminum, lead, tin and other nonferrous metals. Measured according to the site, which accounts for about 15% of the garbage, if not processed directly into the converter, will increase the difficulty of the process, increase the smelting time, due to the impact of non-ferrous metals, will reduce the purity of steel, especially smelting performance The varieties of steel, the use of clean scrap more favorable.

4. The increase in proportion of the heap. Because ordinary internal voids reduce scrap processed, increasing the density, so that the proportion of processed pure scrap heap scrap heap larger than normal gravity, the determination of similar scrap processed through crushing, heap proportion increased 2-3 times, will help shorten the time to scrap furnace installed, shorten the refining cycle. In particular for the converter conducive Bowl counterweight, very popular.

5. pure cost-effective than ordinary scrap scrap. Scrap metal recovery due to the high purity, through our ordinary scrap and scrap pure economic analysis, at the current price level, pure scrap prices (output 17%) than the average scrap prices (output 10%) high 300 yuan / ton, the use of pure economic efficiency than ordinary scrap scrap.

6. scrap processing pure raw material requirements are relatively relaxed. At present, the thickness of ordinary scrap Jigang purchases greater than 3mm, while pure scrap processing scrap materials needed to control the thickness of 1mm-4mm. Expanding the use of scrap, such as scrap scrap car shell, a bicycle frame etc. attached to the surface of waste paint, and the thickness of the paint more other reasons, it is difficult directly into the furnace, the use of this part of the resources are limited, through the crushing process, can be effectively The use of this part of the resource. However, due to equipment limitations, the current PSX-6080 crusher production line processing scrap over 6mm thickness is very difficult, the larger thickness can not be as pure scrap scrap materials.

Currently pure scrap processing and production processes need to be further improved, the production process of the noise and dust problems to be solved, otherwise pure scrap processing environment and the number of production will be strictly limited. Mechanical failure scrap crusher also more continuous production level is not high, so that the production capacity of the equipment can not be fully realized.

|

business consultation

business consultation